Located in Huidong, Liang Shan, Sichuan province, Xiao Long Tan photovoltaic power plant has 30MW capacity with 30 arrays. This is the first photovoltaic project of SCMEC as the promoter in China.

The following data shows the plant status within 25 years:

Average Output: 4406.4 GW

Average Operating Hour: 1465.8 Hrs

1. Earning Guarantee of Scientific Site Selection

After collecting data, inspecting site, comparing scheme and measuring site photometry, the ultimate PV power station has been located:

East Longitude: 02°40’23.70”

North Latitude: 26°35’10.50”

Site selected by professional team provides several advantages state below:

1.1 Good solar radiation and meteorological condition provide higher generating capacity.

Readings from meteorological station, NASA and SOLAR GIS indicate an annual horizontal radiation of 6321.1MJ/m² at site, which is categorized as Solar Belt. Altitude of 2450 - 2850m, annual average temperature of 10.2°C, perennial wind speed of 2- 3m/s and clean air uprate the output of photovoltaic array.

1.2 Short transmission line, lower investment, lower line loss

Plant connects to Liang Shan Grid directly in 35KV line, which guarantee a lower line loss.(4.345km length, around 0.5% line loss rat)

2. Professional Operation and Engineering Supervision

Guided by the management principles of science, competence, unification and efficiency, the elite team charges the Photovoltaic Power Plant.

2.1 Short construction period

The plant filed in Sichuan Development and Reform Commission on Jul,7th,2014; obtained the construction permit on Aug,20th,2014; started on Sep, 23rd, 2014; succeeded in synchronization on Feb, 12TH, 2015 and full load operation accomplished on Mar, 26th, 2015. The trial running ended on April, 5th, 2015 successfully. Till now, the plant is well operating in good condition. Except for force majeure, the actual construction periodonly takes 4 months.

2.2 Complete Documents Procedures

All the licenses & permits & certificate have been acquired before construction finishing. All these documents have guaranteed plant legally running and stable revenue.

2.3 Long-term Stable Operating

Since the first unit (Unit 2) operating on Feb, 12th, 2015, the other two units finished commissioning within 2 months. Benefited from high-quality operation team and their scientific management system, plant actual generation output is 4880GW/yr, which is far more than expectation.

3. High Return on Investment

Based on the rich experience of many international projects, we are expert in capital management and ROI increasing.

According to the first half year actual generating capacity data, payback period is 8.69 year. ROI is 8.35%, ROE is 26.35%, IRR on of asset is 11.24%, IRR of capital is 41.46%, much higher than other photovoltaic plants in the same size and district.

4. Highlights of upgraded intelligent O&M system

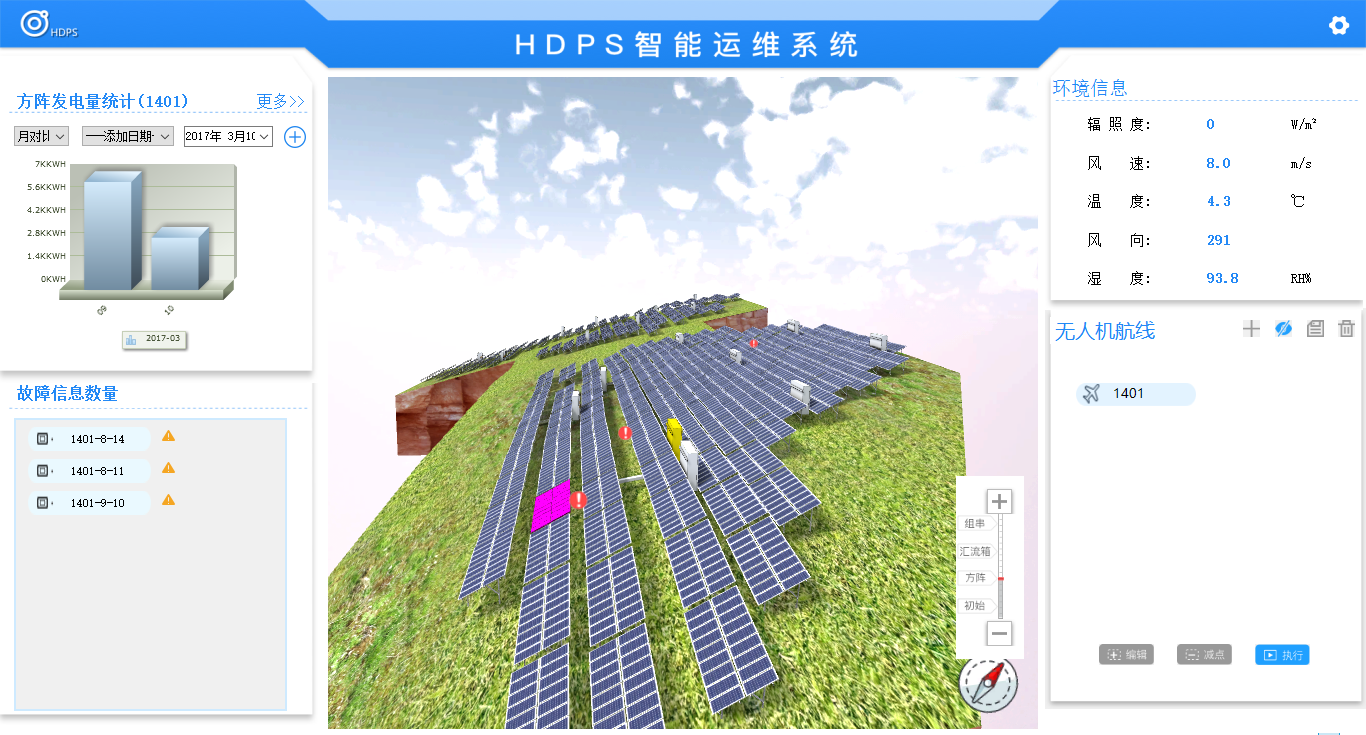

System is based on the 3D models, integrates the original operation data, alarm data, engineering data and actual erection data by the pre-programmed algorithm running at backend, thus enable the station owner, management and O&M people, as per his desire, promptly know the latest information in the direct and visual ways.

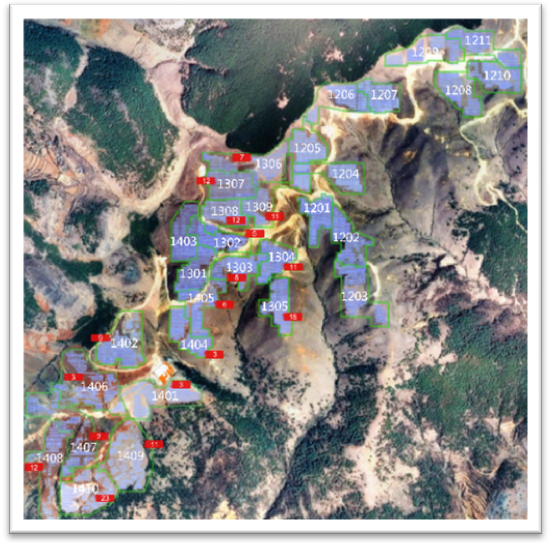

Implementation philosophy is first to set up 3D model according to the site actual equipment arrangement, use it to link and correspond engineering numbering with the computer-monitor numbering and flag the physical location. Second, combine the acquired remote-measuring data, store and process, then display visually the station normal and abnormal operation in the 3D model. Third a drone is introduced for high efficiency normal and malfunction inspection, to integrate with the routine management platform, to support the inventory management. It also helps to analysis the O&M optimization. 30% of personal cost may be saved by this intelligent system as per our estimation.

Main functions include:

Ø Basic systems

To provide overall data initialization including 3D modeling and maintenance, drone route design and maintain, user &

procedure set up, management & maintain

Ø Data acquisition

To realize the data sharing and exchange among computer-monitoring, drone, meteorological acquisition and predication,

luminous power system by using the open data port provided by 3rd party.

Ø Smart cruise inspection

By using the drone, to cruise routinely as per the designed route, to patrol triggered by malfunction and unexpected incidents,

to store in sorts the video, so that the personal cost can be down and the efficiency up.

Ø Data display

Based on the 3D models, to intensively display the operation, power generation and malfunction by different dimension and size.

Ø Operation analysis

By using the remote measuring data , established a specific platform, to form the possible problem component list by comparing

the similar history background, the neighboring component under the similar situation. So that to find the problem at the earliest

to enhance the power generation.

Ø O&M management

In combination with the site formality and table processing for maintenance and storage management, assisted by s application at

cell phone side to ensure time and cost saving.

Ø Mobile App application

A specific app was developed and integrated for in time instant mission and incident remote push, so that related people and boss

in headquarter office can immediate manage the first hand information and response at no time.

HDPS Intelligent O&M System

Malfunction Location By Drone